People spend their entire lives to solve problems.

About Us

We help you look more into the future and find solutions that improve all aspects of your operation to show you how automation can help you grow your business.

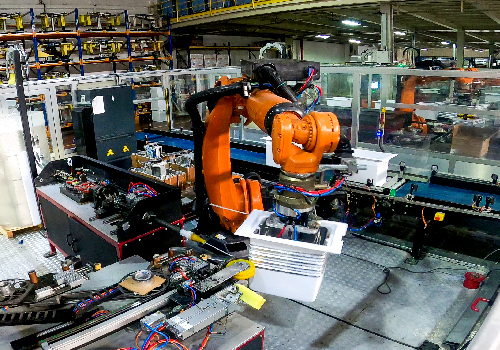

With advanced robot simulation software, we ensure that you get the most efficient system possible, and we fully test the systems that comply with the industry and your company’s safety standards before they are put into operation on the production floor.

Once your system is installed, we provide ongoing maintenance, training, and support to your employees to ensure they remain at their highest performance.

We are in a different position than our competitors in industrial automation.

We continue to grow by making innovative and technological contributions to our industry.

We develop software and hardware for flexible production.

We invest more in Research and Development to stand out in the global competition.

We focus on our customers and only their needs.

Let’s Solve Problems – Together

Past to Today Eurobotik

Intelligent Spray-up system was developed.

2-axis system that selects the process according to the application recipe of the product and sprays the chemical application with the image processing method with the camera

Shoe sanding and spraying robotic system concept was developed.

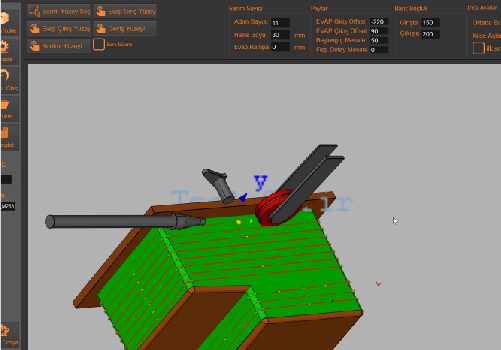

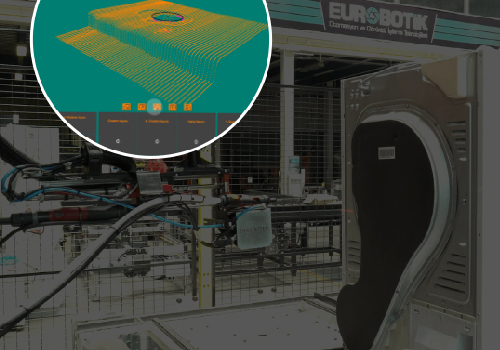

Toolpath removal software was developed over 3D data.

Developed offline robot programming software.

Special robot tool calibration software has been developed together with the robotic CNC machining system.

An easy robot programming system with camera was developed.

System in which robot tool paths are created by tracking human wrist movements with infrared camera

Intelligent Quality control system

Quality control system that performs geometric measurement control at 77 points on each piece that comes out after the welding process in the welding line.

Smart robot program adaptation software was developed.

Smart robot program adaptation software was developed.

The software that detects the changes in the products with image processing and performs the robot program adaptation

Thermoform plastic laser cutting prototype cutting cell was developed.

Evap wrapping prototype cutting cell was developed.

Offline programming software was developed for the Evap winding process.

Special offline programming software was developed for the laser cutting process.

Technopark Istanbul R&D Office was opened.

Developed plastic laser cutting line.

A fully automatic, 6 robotic cutting line solution that can perform cutting applications of many different parts used in refrigerator production in the white goods industry.

Developed Evap Winding Cell with 3 robots.

Aluminum welding system with 2 robots was developed.

Application Center was opened in Gebze, Kocaeli.

A modular plastic laser cutting cell structure was developed.

A fully automatic, 3-robot cutting cell solution that can perform cutting by taking products directly from the thermoform production line with transport robots in new modular plastic cutting cells.

Robotic machine feeding process was carried out.

Robotic condenser banding system was developed.

Robotic laser cutting cell was developed for ballistic and composite trimming and cutting application.

The robotic smart screwing cell was developed.

Robotic integration was realized in the Show and Show industry.

In the MESS 60th Anniversary organization, synchronous robotic programming and system installation were carried out with a general introduction scenario with 6 robots.

Laser cutting method patent was obtained for high quality trim and cutting processes of nonmetals with laser technology.

Our robotic trajectory recording arm product has been patented.

The patent of our product, which facilitates the ergonomic movements that can be made by humans, by transferring them to the robot program, has been patented.

The robotic sealant / siliconization cell was developed.

A robotic sealant cell was developed in which glass and metal materials are combined with each other by applying silicone.